The hanging of the bells uses Taylors’ standard small bell geometry for hanging the bells of below about 5 cwt tenor.

However as the bells are so small, the distribution of mass within the rotating system has been adjusted to give a relatively slow turning speed, similar to the middle six of the current Bellfoundry tower (about 2.25 cwt).

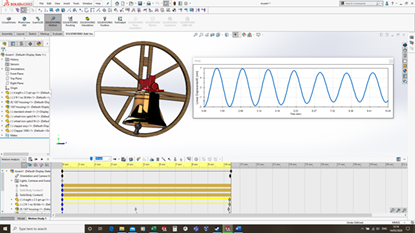

The movement of the bell was modelled in computer aided design software

(Image Solidworks)

Other considerations for the bells include top roping the pulley so that the sally does not go through it, bespoke headstocks, hard-wearing plastic pulleys, and snooker balls on the clappers!

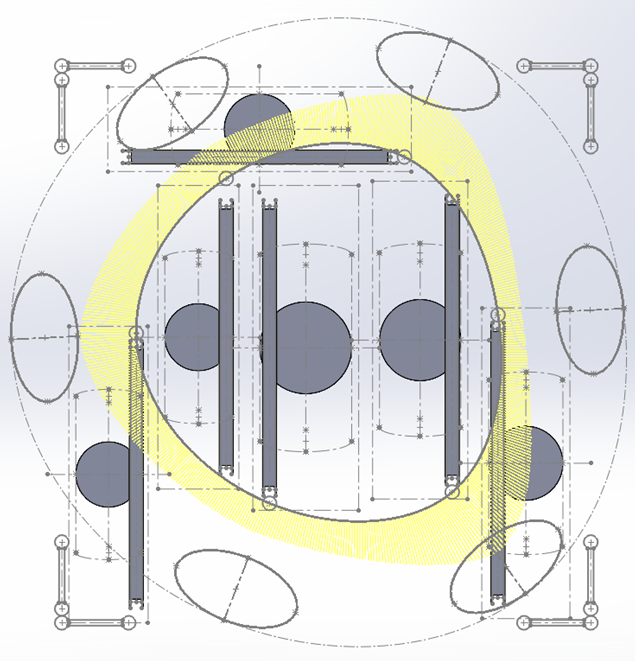

This picture shows the completed frame. The access hatch is visible to the left, note the top hung pulleys so the sallies don’t go through them, and the H frames which are painted red for visual effect.

Frame Layout

This has also needed careful consideration, with the need to keep a good circle for the ringers within or outside the frame structure, whose width is defined by the maximum permissible towing width of 2.55m.

The heaviest bells are hung in the centre to add stability, and there is room for access up through the bells.

The frame itself, like the rest of the structure, has been made from aluminium for a maximum strength to weight ratio. Everything about the design is predicated on making sure the whole package including the trailer does not exceed 1800kg.